Add to Cart

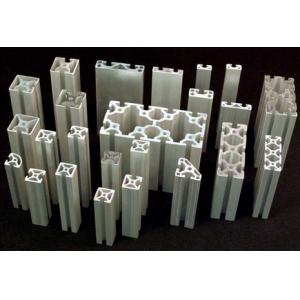

Mill Finished Aluminium Profile System Automation Equipment Use / Assembly Line / Production Line

We can design, manufacture various types of purpose-built LCD TV/LED TV assembly lines /production lines according to the specific requirements of our customers .

1) aluminum alloy:AL6063/6061/6005 or as for per customers's require.

2) finish. various anodizing colors,powder coating,paiting or mill finish.

3) Surface treatmen: andozied,electrophoresis, powder coating(any color),mill finish,color painting,and so on

4) Length: according to clients' need

5) Packing: with plastic film and wrapped with kraft paper.or meet the clients' requires

6) Usage of the aluminum products: decoration,furniture,windows and door frame,curtain wall,conatruction,etc. We have the Extruding machine (4500T) .

7) Certificate: ISO9001.ISO14001

Order,payment,terms,shipment

1, Minimum order: 500kg per trial order 1 piece of sample free of charge provided by approval and kept for future mass production.

2, Sample Lead Time: 25 working days(15 days for making the tool and 10 days making the samples. Before sending the samples to customer, samples should pass strict test in our lab. )Production Lead time: it depends on customers' order quantity ( 30 working days after deposit).

3, Payment: (Can negotiate with customers, our usual practices are as follow)

4, Tooling:100% prepaid by T/T.

5, Parts:30% upon order confirmation and balance before delivery by T/T

Applications:

Mainly used for industrial production , such as automation equipment , enclosure of the skeleton and the companies according to their own customized mold machinery and equipment , such as assembly line conveyor , hoist, dispenser, testing equipment, shelves , etc., electronic machinery industries and clean room with a gain majority.

Competitive Advantage:

1 to facilitate the construction : a modular and multi-functional, without complex design and processing , you can quickly frame the ideal machinery coat.

2 beautiful and practical : light and high rigidity, simple and beautiful appearance .

3 Strong scalability : The unique T-type, groove design , the installation of components without demolition profiles can be installed anywhere in the nut screws , modified equipment is simple and quick.Aluminum extrusion profile , is rod by hot melt extrusion , to obtain different cross-sectional shapes of an aluminum material . Aluminum production processes including casting, extrusion and painting three processes . Among them, the color include: oxidation, electrophoresis coating, fluorine carbon spraying, powder coating, wood grain transfer printing and other processes.

Air container assembly line , Led downlight bulb light assembly line ,160 ton powder press assembly line