Add to Cart

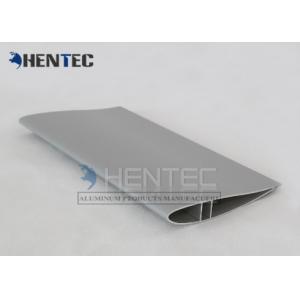

Aluminium Industrial Fan Blade Aluminum Extrusion Profile For Cooling Blade

Descrition:

Hentec Industry Co., Ltd is the vendor of BOSCH, SHARP , professional at aluminum extrusion profiles, both semi and final products, such as Aluminum fan blade , LED aluminum bracket, aluminum door, aluminum window, aluminum guide rail, aluminum fencing and all kinds of industrial and building aluminum profile, square, round, flat, oval, angle, irregular and all types according to the customers' drawing.

| Brand Name | Hentec |

| Material | 6000 series, normal material such as 6063,6005,6061,6060, special material such as 6082. |

| Thickness | General profile thickness:0.8-5.0 mm; Anodized protection thickness:8-25 um; Powder coating color thickness 40-120 um. |

| Diameter | 5-800mm |

| Color | Silver, bronze, black,gold, blue, grey, champagne, bright, as your requests. |

| Temper | T4 ,T5 ,T6 |

| Shape | square, flat, round, hollow, oval, triangle, U-profiles, L-profiles, T-profiles, H-profiles, customized available |

| Surface Treatment | Mill finish, anodic oxidation, powder coating, eletrophoresis, PVDF coating, all kinds of high simulation wood grain processing, etc. |

| Products Classification | 1) General aluminum profiles: various shapes of pipes and tubes, angles, T or U shapes etc. |

| 2) Industrial aluminum profiles: Aluminum Fan Blade , heat sink, aluminum enclosures, closet frame, furniture frames, LED lighting, Ads screens frame, protect fences, Ladder, Guide Rail etc. | |

| 3) Construction aluminum profiles: Aluminum doors & windows, Sliding Windows, Roller shutter door, Curtain track | |

| 4) OEM & ODM: accept customers' own designs and drawings of aluminum products | |

| Deep processing: | Cutting, punching, drilling, tapping, milling, bending, welding etc. |

| Manufacture technological process | Aluminum ingot → Melting and casting → Extrusion → Surface Treatment → Test →Packing → Warehouse → Delivery |

| Certification | ISO 9000; ISO 9001; ISO 14000 |

ADODIZINMG QUALITY | ||||

Grade | corrosion resistance | abrasive resistance | ||

CASS test | alkaline dropping test | sandtrial Abrasion coefficient f,g/um | ||

hours | grade | |||

AA10 | 16 | ≥ 9 | ≥ 50 | ≥ 300 |

AA15 | 32 | ≥ 9 | ≥ 75 | ≥ 300 |

AA20 | 56 | ≥ 9 | ≥ 100 | ≥ 300 |

AA25 | 72 | ≥ 9 | ≥ 125 | ≥ 300 |

| POWDER COATING QUALITY | ||||||||

| Gloss values | Thickness(um) | color variation | indentation resistance | adhesion | impact resistance | cupping test | presentation quality | |

| Max Thickness | Min Thickness | |||||||

| 60 | ≤ 120 | ≥ 40 | Color should be consistent with the sample color | ≥ 80 | 0 | No cracking and shedding phenomenon after the front impact test,small fine lines around the concave is allowed | No cracking and shedding phenomenon after the cupping test ( 6mm indentation depth ) | |

Competitive Advantage:

1) More than 30 sets of production lines for casting, extrusion, anodizing, powder coating, thermal break, electrophoresis, PVDF, deep processing, etc.

2) Strict quality assurance and inspection measures will never let any imperfect products be out of our company.

3) Awarded various honors, such as "National Quality Exemption", "Famous Brand", etc by the government and enjoy a good reputation among overseas markets.

4) Strong R&D team .

5) 15 years OEM ODM factory experience;

6) Made in China gold and audited supplier ;

7) Most advanced equipments and production lines to make sure your project with excellent quality in very short time;

8) Business contract and non-disclosure agreement are always ready for you;

9) Customers can easily reach us rapidly(24*7 Hours Available);