Add to Cart

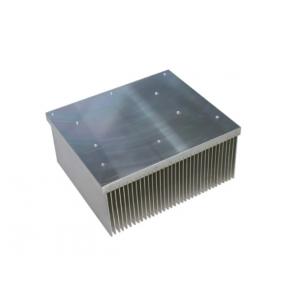

Customized Heatsink Extrusion Profiles Aluminium Radiator High Performance

| Product type | Heat sink of Foreced Air cooling,natural air cooling , water cooling, Heat pipe, LED, electriacal vehicle, etc series. |

| Material | Aluminum 6063, 100% pure electrolytic aluminium, Thermal conductivity:201W/m.k, aluminum content:98%. |

| Sizes | Have more than 1000 existing modes, also can be customized design. |

| Production Process | Profile extrusion, Cutting,Deburring, CNC Processing, Stamping,(drilling holes, tapping,Chamfering,Milling),(Brushing, Sandblasting,polish)Surface Treatment(Anodization, Painting, E-coating), 100%Inspection, Assembly,Package, etc. |

| Surface oxidation | Black anodizing, Clear anodization,Painting,E-coating, etc. By your request. |

| Application | Computer.Data Server.New energy vehicle ,SVG/SVC/ APF/ frequency converter, inverter, charging device. Welding machine. Welding controller/ power supply(induction heating/ rectifier/ inverter power/ electroplate power/ SMPS/ military / laser power supply/ ) power regulator/ soft start/ broadcast communication( base station/ signal shielding brodadcast transmitter, power amplifier ) electronics, etc. |

| Devices | extrusion lines,Cutting machines, CNC machines, Stamping machines,milling machines, drilling machines,polish machine,laser machines,anodization line,assembly lines. etc. |

Our Advantages:

1) More than 35 sets of production lines for casting, extrusion, anodizing, powder coating, thermal break, electrophoresis, PVDF, deep processing, etc.

2) Strict quality assurance and inspection measures will never let any imperfect products be out of our company.

3) Enjoy a good reputation among overseas markets.

4) Strong R&D team and over 130 national patents.

5) 17 years OEM ODM factory experience;

6) Made in China gold and audited supplier ;

7) Customers can easily reach us rapidly(24*7 Hours Available);

8)Small order is accepted

Applications:

Aluminum heat sink is widely used on Machines , cars , lighter ...

Specifications:

1. Primary Technical Data

1) Chemical composition

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Impurity | Al |

| 6063 | 0.2-0.6 | 0.35 | 0.1 | 0.1 | 0.45-0.9 | 0.1 | 0.1 | 0.1 | 0.15 | Rest |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | 0.15 | Rest |

| 6060 | 0.3-0.6 | 0.1-0.3 | 0.1 | 0.1 | 0.35-0.6 | - | 0.15 | 0.1 | 0.15 | Rest |

| 6005 | 0.6-0.9 | 0.35 | 0.1 | 0.1 | 0.40-0.6 | 0.1 | 0.1 | 0.1 | 0.15 | Rest |

2) Mechanical property

| Alloy | Temper | Tensile strength | Yield strength | Elongation |

| 6063 | T5 | ≥ 160Mpa | ≥ 110Mpa | ≥ 8% |

| T6 | ≥ 205Mpa | ≥ 180Mpa | ≥ 8% | |

| 6061 | T6 | ≥ 265Mpa | ≥ 245Mpa | ≥ 8% |

Competitive Advantage:

We can offer professional Manufacturing and exporting service, OEM/ODM for Metal & Plastic parts in China. All the parts manufactured by CNC Lathe & Milling Machine Center.